As industries strive to keep pace with the demands of a rapidly evolving landscape, sustainability and waste reduction have emerged as challenging and critical priorities for most companies across the globe. Among the strategies gaining momentum is Waste Stream Mapping (WSM), a holistic approach that examines and enhances waste management practices. For businesses across diverse sectors aiming to establish Zero Waste Programs, WSM is increasingly recognized as a pivotal tool for achieving success. This blog explores the concept of WSM, its benefits, and the implementation of successful Zero Waste Programs in various sectors.

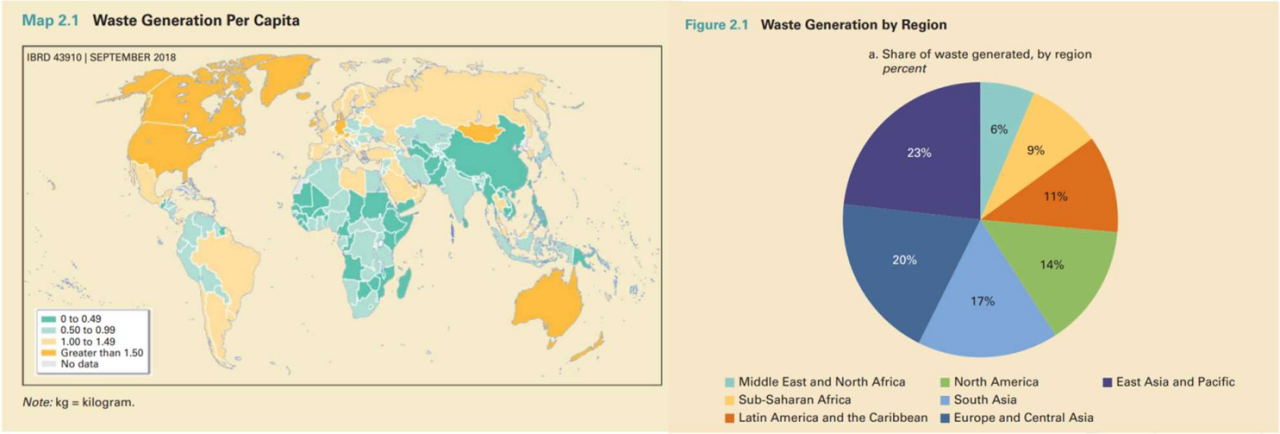

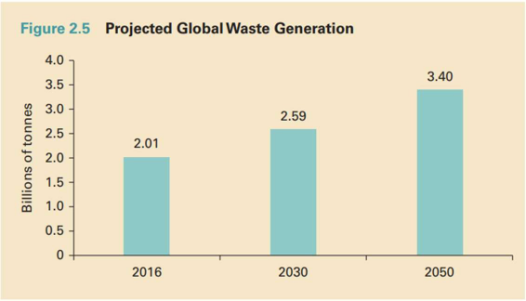

According to the World Bank’s “What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050” report, the world generates 0.74 kilograms of waste per capita per day, yet national waste generation rates fluctuate widely from 0.11 to 4.54 kilograms per capita per day. Waste generation volumes are generally correlated with income levels and urbanization rates. An estimated 2.01 billion tonnes of municipal solid waste were generated in 2016, and this number is expected to grow to 3.40 billion tonnes by 2050 under a business-as-usual scenario. Globally, about 37 percent of waste is disposed of in some type of landfill, 33 percent is openly dumped, 19 percent undergoes materials recovery through recycling and composting, and 11 percent is treated through modern incineration.

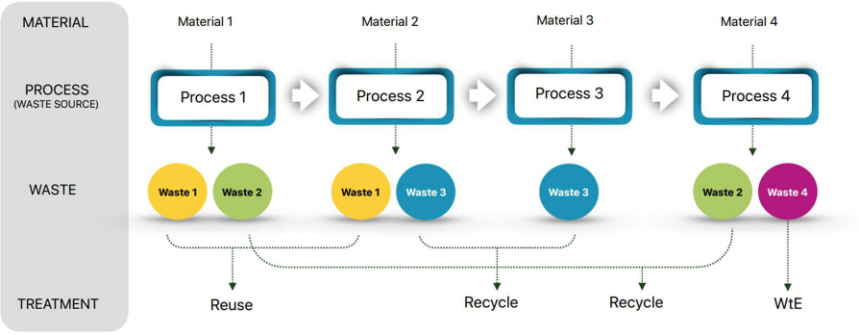

Waste Stream Mapping is a systematic approach to understanding the flow of materials and defining the type of waste within an organization. It involves mapping out the entire lifecycle of materials, from procurement to disposal, to identify inefficiencies, areas of waste generation, and opportunities for improvement. By visualizing the flow of materials and waste, businesses can gain valuable insights into their processes and make informed decisions to reduce waste.

Adopting WSM and moving towards a Zero Waste Program involves a few key steps:

Over the years, we have had the privilege of working with electronic industries, guiding them towards effective waste management strategies, supporting the implementation of Zero Waste Programs (ZWPs), and getting them certified for UL 2799 certification.

One such case is of a leading electronics manufacturer that embraced WSM. Facing significant waste management challenges, they implemented WSM and, within a year, halved their waste generation, saved costs, and made a positive impact on the environment. This example illustrates the profound effect WSM can have.

Waste Stream Mapping is a powerful tool that can help businesses of all sizes achieve their Zero Waste goals. By understanding the flow of materials and waste within their operations, companies can identify opportunities for improvement, optimize processes, and reduce waste generation. Implementing a Zero Waste Program through WSM not only benefits the environment but also contributes to cost savings and improved operational efficiency. Together, we can create a world where waste is minimized, resources are conserved, and sustainability is the norm.

If you’d like to learn more about our services, please message us, and one of our SMEs will respond promptly.